Customized Non-Woven Bag Service

01

Company Introduction

Anhui Bag King Environmental Technology Co., Ltd. was established in January 2024. The company integrates product research and development, production, and trade, dedicated to promoting the development of eco-friendly packaging products. As a holding subsidiary of Fujian Nanwang Environmental Technology Co., Ltd. (stock code: 301355), Bag King boasts advanced domestic production equipment and a complete bag-making process, with a total operational area of approximately 95,000 square meters. The company has more than 100 main production equipment units for blowing fabric, printing, and bag making, as well as nearly 30 sets of inspection and testing equipment, with an annual production capacity of about 1 billion non woven bags. The company has been certified for the Quality Management System (ISO 9001:2015) and the Occupational Health and Safety Management System (ISO 45001:2018). It also has a professional technical research and development team and currently holds eight core patent technologies that are leading in the industry.

As a drafting unit for the “Group Standard for Eco-Friendly Non-Woven Bags for Takeaway (T/HBFPA017-2023),” Bag King will aim to lead the industry in non-woven fabric bags, aligning with Nanwang’s vision to become the most trusted partner for world-class brands.

02

Production Capacity

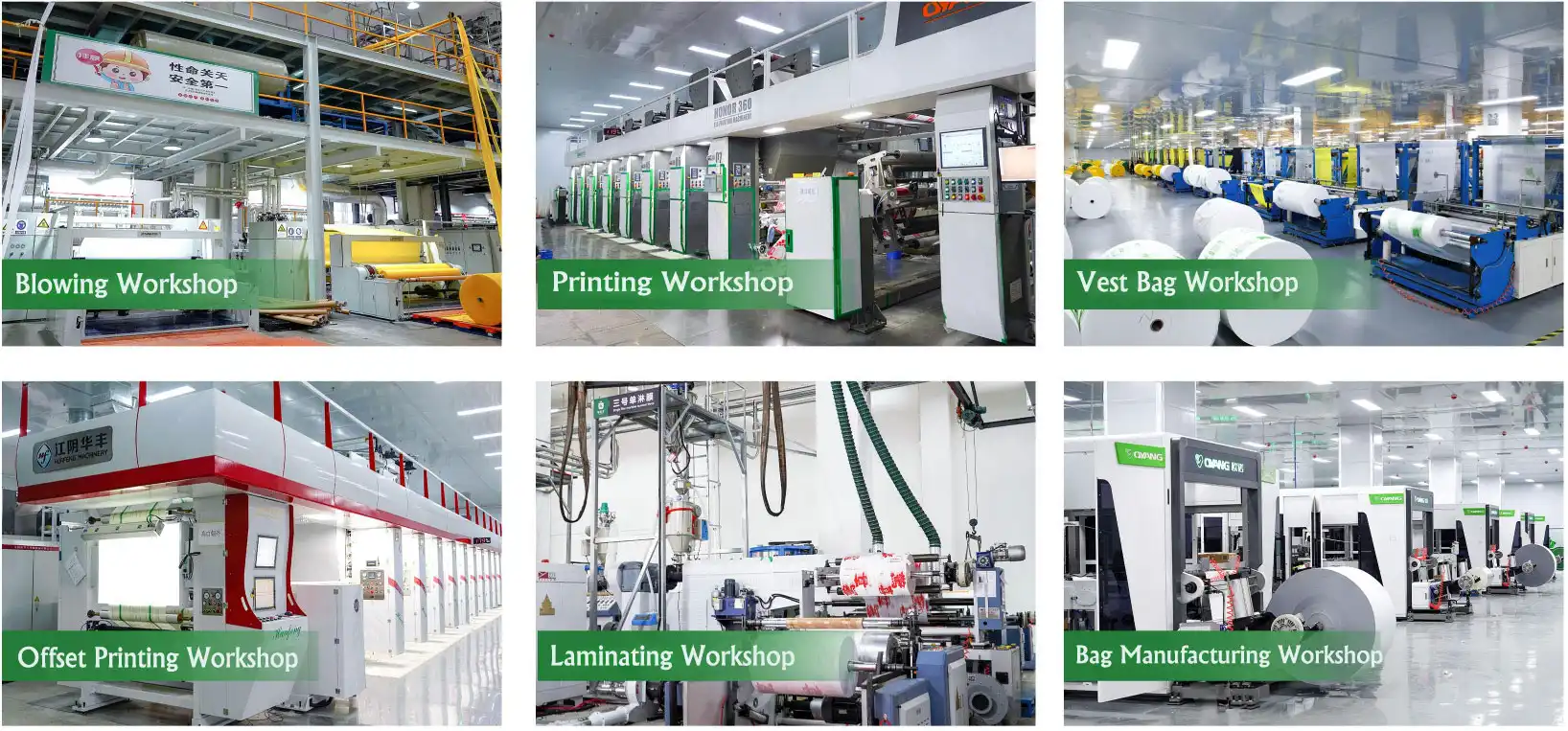

Bag King establishes dedicated project teams for long-term clients, providing the best overall printing and packaging service solutions based on customer needs through specially designed service teams and exclusive production line equipment.

Bag King’s workshop includes a fabric blowing area with a weight range of 10g-180g and a maximum width of 3.6 meters, achieving a daily output of over 25 tons. The printing workshop uses imported machines, with 6-color machines operating at speeds of 300-350 meters, 8-color machines reaching up to 350 meters, and 9-color machines at 260 meters. Additionally, the bag-making workshop features 48 high-speed bag-making machines, producing 3 million bags per day, and 35 vest bag-making machines with a daily output of 1.5 million bags. This high-speed, efficient, and stable production capability positions us as the largest and most comprehensive manufacturer of non-woven fabric bags in China, further reflecting Nanwang’s comprehensive layout in the non-woven fabric sector and the broad prospects for future business development.

03

Main product

Vest Bags

Our vest bags are manufactured with fully automated processes, ensuring high efficiency and consistently stable quality. We utilize a one-time forming process combined with heat-sealing or ultrasonic welding for robust construction. These bags offer broad compatibility for various uses and are ideal for a wide range of retail and supermarket environments.

One-Step Forming Bags

One-step forming bags are categorized into flat mouth series and sealing series. The flat mouth series includes four-finger bags and tote bags, while the sealing series consists of double-high pockets and high-low pockets. These bags are produced using fully automated machinery, ensuring high efficiency and stable quality. They are manufactured through a one-step forming process with ultrasonic welding techniques. The products have a wide range of compatible applications and can be used in various retail and supermarket scenarios.

Thermal Bags

Thermal bags are commonly used for takeout, featuring excellent sealing properties and effective thermal insulation. They offer superior load-bearing capabilities and are reusable. Thermal bags can be produced using fully automated machinery or handcrafted, ensuring stable quality. These products have a wide range of compatible applications and can be used in various retail and supermarket scenarios.