Quality Control of Nanwang’s Paper Bag

As a drafting unit for paper bag industry standards, Nanwang is equipped with the industry’s most advanced and comprehensive laboratory facilities. We’ve established stringent internal quality control standards, encompassing strict supplier audits, raw material inspection, and manufacturing process oversight. Additionally, we have set up a robust traceability system for our products, enabling quality traceability to be completed within 24 hours.

Raw Material Testing

- Physical Properties: Basis weight, odor, folding endurance, bursting strength, stiffness, tensile strength, tearing strength, smoothness, brightness, opacity, dust content, thickness, moisture content, water absorption (Cobb test), grease resistance (KIT method and hot oil test), etc.

- Food Safety Indicators: Fluorescent substances, potassium permanganate consumption, heavy metals (calculated as lead), formaldehyde, total migration, microbiological tests (3 items), etc.

- Ink Inspection: Color, odor, pH value, heavy metals (multiple elements), etc.

- Adhesive Inspection: Viscosity, solid content, heavy metals (multiple elements), etc.

Paper Bag Manufacturing Control ——

Paper Bag Manufacturing Control

In the production process of eco-friendly paper bags, 14 types of inspections are required:

Dry rub resistance test of printing ink、Oil rub resistance test of printing ink、Drop test、Static Weight Bearing Test、Dynamic lifting test、Handle pull test、Swing test、High and low-temperature resistance test、Grease resistance test、Fluorescent substance test、Seal adhesion strength test、Basis weight detection、Dimensional measurement、Adhesive bonding strength test。

To complete the above inspections, we need to invest at least 660 paper bags per day.

Handle Pull Test

Color Proof

Static Weight Bearing Test

Fourteen tests are required in the food packaging production process:

|

Product Type |

Test Items |

|||

|

Paper Cup |

Leakage |

Ice Cube |

Cup Body Rigidity |

Specifications(Measurement) |

|

Paper Straw |

Soak |

Specifications |

|

|

|

Hamburger Paper |

Grammage |

Wax Coating Weight |

Spot Resistance |

Ink Penetration |

|

Printing |

Ice Friction |

Soaking Decolorization(ink) |

Abrasion Resistance |

|

|

Paper Bag / Paper Box |

Abrasion Resistance (Dry Friction) |

Soaking Decolorization(ink) |

Waterproof |

High and Low Temperature |

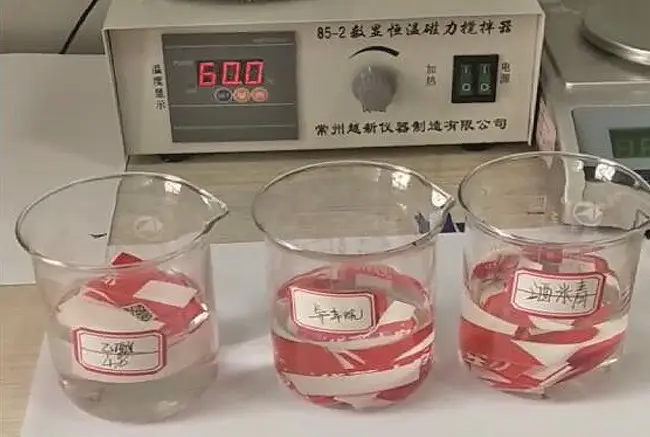

Abrasion Resistance Test

High And Low Temperature Test

Immersion Decolorization Test

Perfect and Comprehensive Inspection

Built to meet CNAS laboratory accreditation standards, capable of testing the compliance of paper, ink, and adhesive. The laboratory is equipped with over 100 testing instruments, with a total investment of nearly ten million yuan. The laboratory includes advanced testing equipment such as atomic fluorescence spectrometer, gas chromatography-mass spectrometer, and inductively coupled plasma emission spectrometer, capable of detecting compounds, heavy metals and other projects in raw materials.

01. Physical Testing Laboratory

This section is fully equipped with all the necessary instruments for testing the physical properties of paper, glues, inks, and finished products.

02. Microbiology Laboratory

The microbiology lab conducts microbial monitoring of raw materials and finished products in accordance with China’s National Food Safety Standard GB4806.8. Microbial monitoring and control are also implemented as required by GB31603.

03. Chemical Analysis Laboratory

This laboratory is capable of testing all parameters specified in GB4806.7 and GB4806.8.

04. Simulation Laboratory

The simulation lab performs various tests to mimic end-use scenarios, ensuring products meet performance requirements in real-world applications.

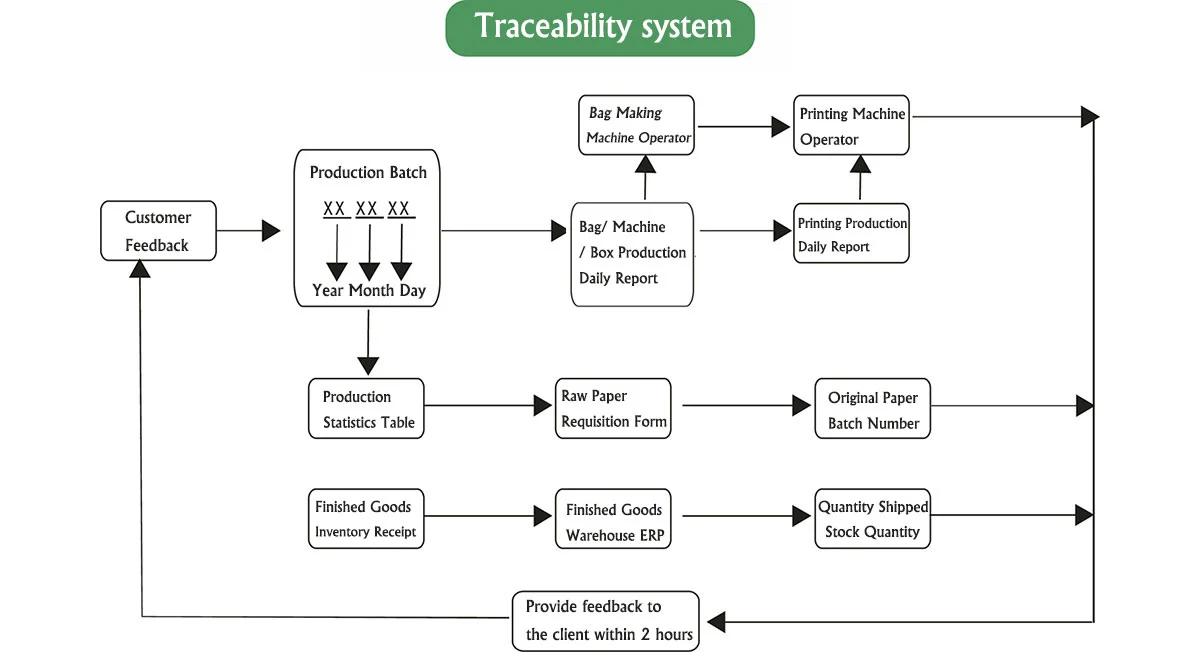

Traceability System

Rapid response —— Product traceability can be completed within 24 hours.

Product traceability can be completed within 24 hours

By assigning a unique traceability code to each product batch, Nanwang ensures every product has its own distinct identification number. Each product batch undergoes a comprehensive traceability system throughout its production process. This system enables data collection and tracking across various stages, including suppliers, raw materials, production, warehousing, sales, market inspections, and consumers. Furthermore, product traceability can be achieved within 24 hours, allowing for a rapid response to customer feedback.